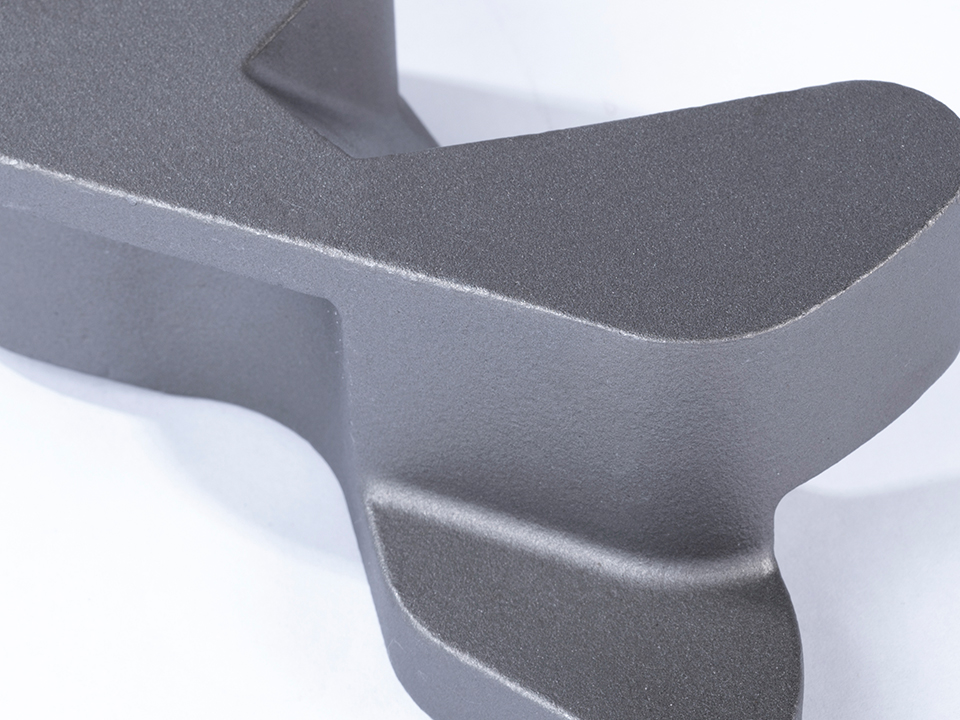

A high-speed shot flow made of steel shots, iron sand or stainless steel shots is sprayed on the casting surface in the shot blasting machine, to remove surface impurities and get a uniform surface. Further surface treatment is needed to prevent rust if this process is used on the castings made of carbon steel, low and medium alloy steel, or tool steel.

Application: all materials other than nonferrous alloys.

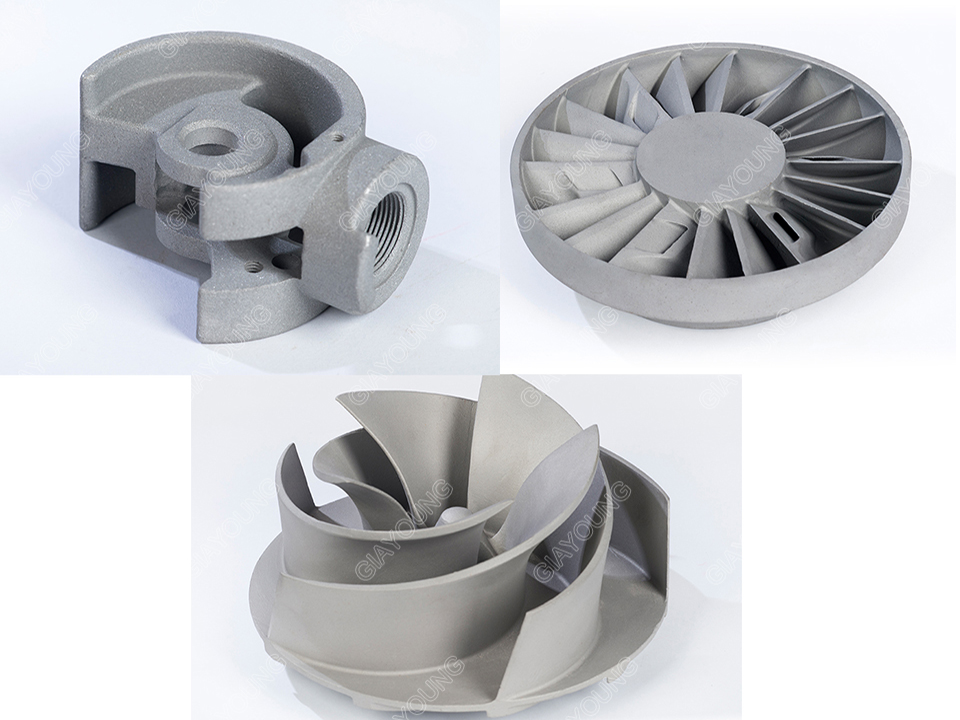

A high-speed sand flow made of quartz sand, brown corundum or glass beads is sprayed on the casting surface with compressed air in the sand spray machine, to remove surface impurities and get a uniform, fine surface. With the effect of the impact, the mechanical properties of the surface of the work piece are improved, so is the fatigue strength. The adhesion between the work piece and the coating can also be increased. Further surface treatment is needed to prevent rust if this process is used on the castings made of carbon steel, low alloy steel, or tool steel.

Application: all materials.

The castings are immersed in passivation solution to remove impurities on the surface and form an oxide film, thus the corrosion and rust resistance of the castings is enhanced. Casting surface after passivation is bright, glossy and aesthetically pleasing.

Application: Stainless Steel, Copper Alloy.

The castings and a lead plate are placed in electrolyte together while the castings act as the anode and the lead plate as the cathode. When DC current is applied, the current density at the positions where burrs and bulges exist on the surface of the product is bigger, and thus burrs and bulges are dissolved faster. This inhomogeneity dissolves the bulges faster and makes the surface smooth and polished. It can improve the surface finish and increase the corrosion resistance of castings. The surface after electropolishing is smooth and with good luster.

Application: Stainless Steel.